Prices haven’t been kind to either PC or console gamers over the last several years. Both the Playstation 5 and the Xbox Series consoles launched in 2020, and almost 5 years later, the consoles cost more than ever.

Tariffs certainly haven’t helped any; but neither has the raw BoM (Bill of Materials) and for both PC and console gamers; this doesn’t show any signs of relenting. TSMC is currently the go-to chip production manufacturer for cutting-edge silicon, and their 2nm process is impressive indeed.

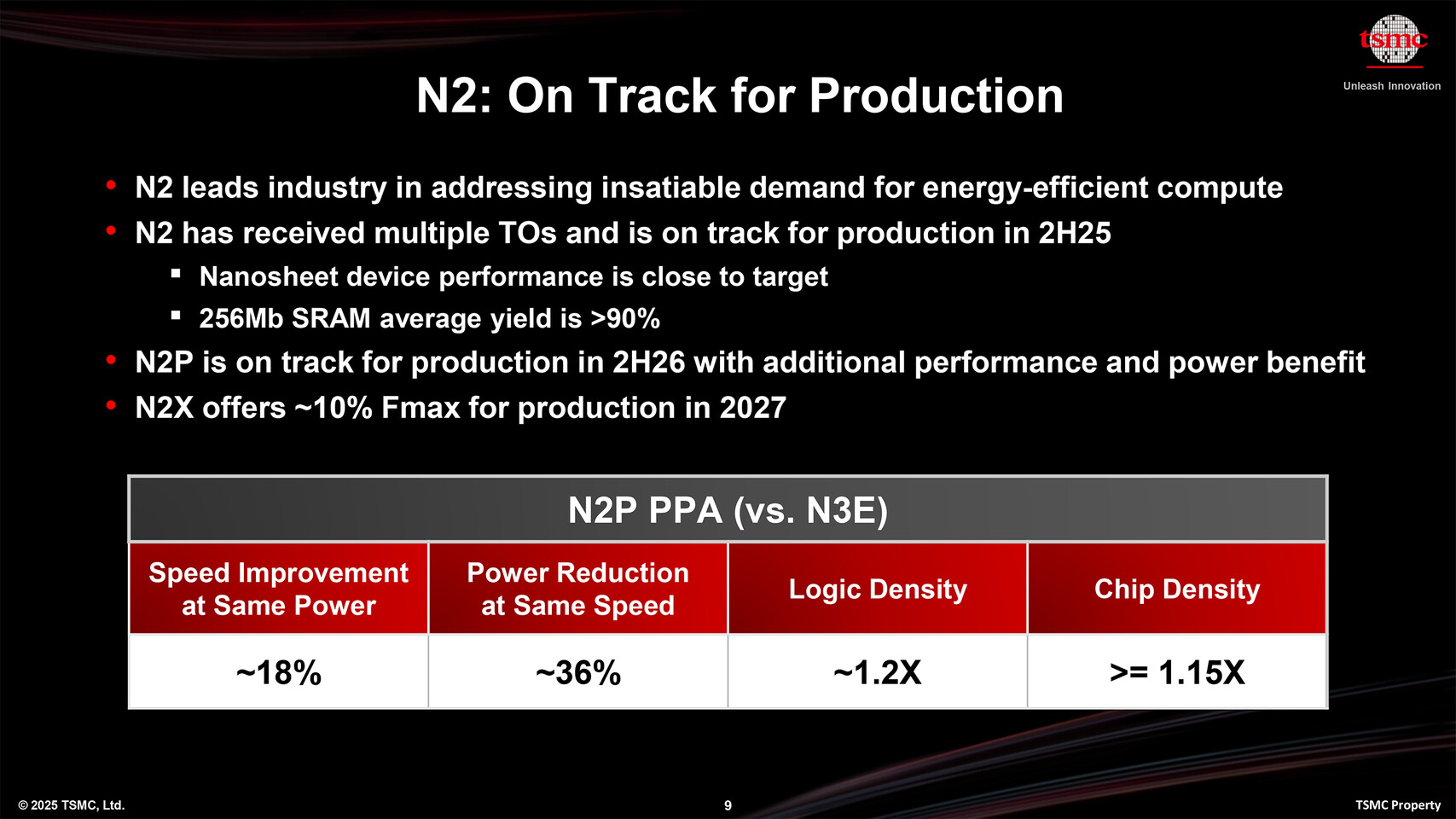

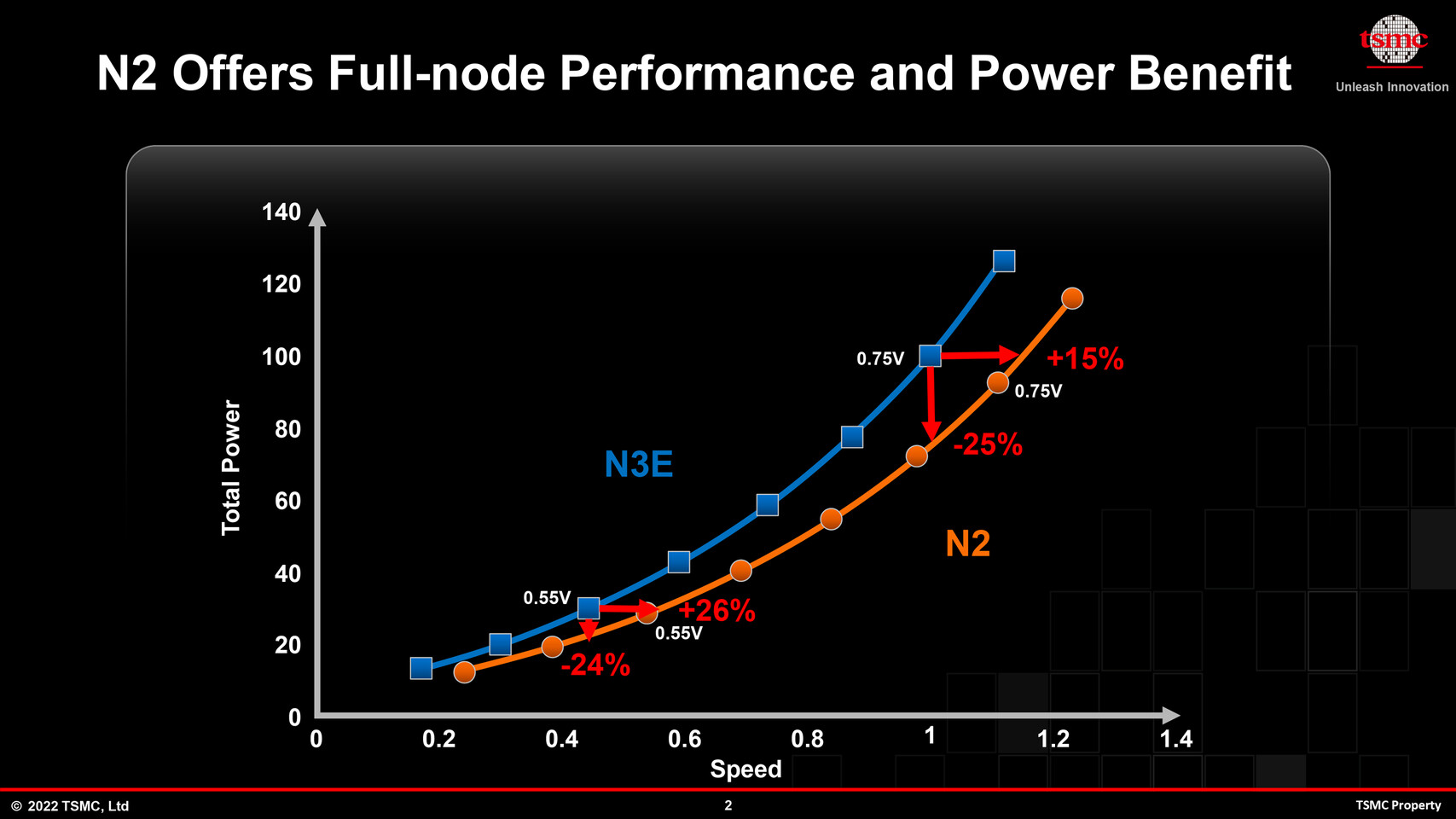

Taking a look at the N2: On Track for Production slide, we can see that in comparison to N3E, the N2P PPA silicon offers 18 percent speed improvement if the same power is provided.

If a vendor maintains the same chip speed a reduction of around 36 percent can be expected. To put this another way, if a chip hits 5ghz on the N3E node, and they then switch to N2P with the same design, for the same 5GHz the chip would consume around 36% energy.

The Logic density is up 1.2x and chip density hits 1.15. There’s a few other nuggets we can garner from the slides, including the 256Mb SRAM yield now exceeds 90 percent; but here’s the thing, the price is going up too.

According to Dan Nysted on Twitter “TSMC’s latest manufacturing process, N3P of the 3nm family, are about 20% higher than the prior generation, and 2nm will be over-50% higher than N3P as price inflation continues to hit semiconductors, media report, citing unnamed supply chain sources. TSMC is not allowing any 2nm (N2) discounts due to its huge production line equipment spend”

I just want you to pause a moment and really think about that, 50 percent higher costs for the N2P process over N3P.

Now, of course, for a games console or a high-end GPU from Nvidia or AMD, this doesn’t equate to the product becoming 50 percent more expensive. But, the silicon certainly isn’t a small part of the cost; and that’s to say nothing of AMD’s future CPUs, smartphone chips and so on.

I’ve frequently lamented on both Twitter and Youtube over the scaling we’ve seen in the past just isn’t what we’re seeing now. And this is of course simply the fact that we’re producing chips so small now, that simply shrinking something down is really tricky. We’re running into a plethora of problems.

Keeping things simple: with transistors getting so tiny and the gaps between stuff shrinking further and further, well, let’s just say it isn’t ideal.

In the days of the Xbox 360 the Xenon CPU initially was produced for the 2005 console debut on the 90nm process, and some 2 years later this was down to 65nm. This meant that chip was smaller, consumed less power, required less exotic cooling and of course, less power delivery.

This in turn reduced the costs – and the chip itself was cheaper to produce. But this isn’t happening now, and in the case of graphics cards from AMD and Nvidia, the dies inside of them are massive.

TSMC does have some competition of course, and with luck Intel’s 1.4A process (for example) will be excellent, but it’s hard to deny it’s going to be very interesting to see how this impacts future GPU products.